PLC-Wizz: The Universal Solution for Every Generation of Industrial Code

In most of the software world, legacy code is treated like something to be replaced or upgraded (or at least apologized for). But in industrial automation, that “legacy” ladder logic from 1985 isn’t just technical debt, it has been the reliable foundation keeping billion-dollar operations running 24/7.

While some facilities are experimenting with modernisation and object-oriented PLC programming, others are still running perfectly good systems built decades ago. And, for the most part, both approaches work exactly as intended.

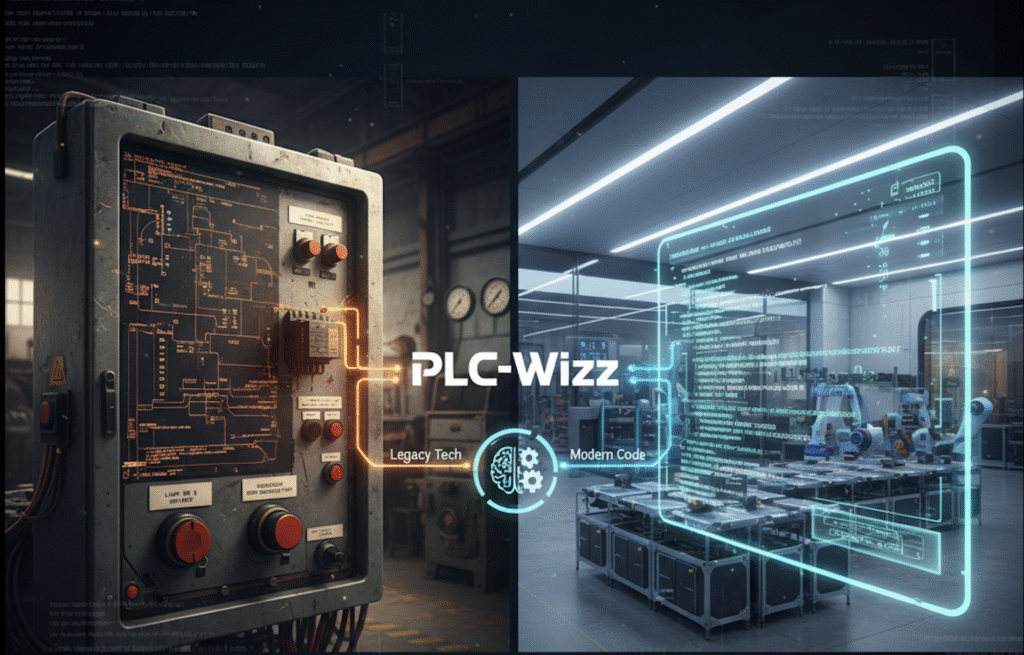

Most firms these days are dealing with at least some level of debate between the old and the new. Do you keep your legacy systems? Or update to get with the times? There are dozens of salient points for each side, but PLC-Wizz supposes a new way: what if you didn’t have to choose?

The Tale of Two Factories

Walk into Factory A, and you’ll find ladder logic diagrams that look like they were drawn a century ago. The maintenance team loves them because they’re visual, intuitive, and when Line 3 stops at midnight, anyone can trace through the logic and spot the problem. These systems have been running well enough for decades, with minimal downtime and predictable behavior.

Across town at Factory B, control engineers are deploying modern software engineering principles with structured text and object-oriented features, leveraging the new IEC 61131-3:2025 standard. They’re building modular, reusable code libraries and embracing abstraction layers that would make any software developer proud.

Both factories are running optimally. Both teams are doing their jobs correctly. And until now, both needed completely different toolsets.

The Modern Wave: Innovation Without Abandonment

While legacy systems continue their reliable service, a parallel evolution is happening. The recently released IEC 61131-3:2025 standard introduces object-oriented programming concepts to industrial automation. Companies like CODESYS are pioneering “Object-Oriented Industrial Programming” (OOIP)—bringing encapsulation, composition, and abstraction to control systems.

This isn’t about replacing what works. It’s about expanding possibilities. Some applications benefit from modular, reusable code structures. Others need the transparent simplicity of traditional ladder logic and older languages. Both approaches work, so why not support both?

But here’s the problem most tool vendors miss: they pick a side. They’re either “legacy-friendly” or “cutting-edge,” never both.

PLC-Wizz: The Everything Solution

PLC-Wizz takes a radically different approach: true universality. Their AI-powered platform doesn’t just tolerate different programming paradigms, it excels with them. With a direct connection to the programming IDE, PLC-Wizz extracts the relevant knowledge and ensures any output has the relevant context when it provides the responses.

Legacy System Excellence with Modern Code Mastery

PLC-Wizz utilizes a custom AI model built just for Industrial Automation. PLC-Wizz provides:

- Intelligent Code Analysis: AI that easily understands decades old code (without even code commentary) alongside the new programming languages, enabling PLC-Wizz to provide instant responses to any query with references. Plus, PLC-Wizz can generate interactive visualisations of key processes with a single click.

- Automated Documentation: Transforms implicit tribal knowledge into explicit, searchable documentation with multiple formats. This documentation can then be updated and shared across teams.

- Advanced Code Generation: AI that understands your existing projects and generates code that can seamlessly integrate with your existing projects. Create new code from visual diagrams or using natural language

- Cross-Language Translation: Seamlessly convert between different languages and programming environments with all their different nuances

The Universal Bridge

Most importantly, PLC-Wizz works brilliantly in mixed environments where both approaches coexist:

- Unified Documentation: Single platform documenting ladder logic, structured text, and everything in between now and in the future

- Incremental Integration: Add modern components to legacy systems without disruption

- Team Collaboration: Bridge the communication gap between traditional automation engineers and software developers

- Maintain Continuity: Ensure new and existing team members are rapidly upskilled and provided the tools they need, so that they can work with any program langauge or projects that they encounter

Beyond the Code: The Human Factor

The brilliance of PLC-Wizz isn’t solely technical. Its strength lies in recognizing that industrial teams are diverse.

For example:

- Veteran electricians who learned on relay cabinets and think visually

- Control engineers comfortable with both traditional and modern approaches

- Software developers increasingly involved in industrial automation projects

- Maintenance crews who need to understand any system they encounter

With a smartly designed and simple interface, PLC-Wizz ensures that you have the tools and documentation you need to be effective, regardless of your background, experience level or the code style you’re working with.

The Economics of Universal Support

From a business perspective, PLC-Wizz’s universal, system agnostic approach makes sense:

- No Forced Migrations: Legacy systems continue operating without expensive rewrites

- Future-Proofing: New projects can use modern approaches without abandoning existing tools

- Reduced Training Costs: One platform serves all programming styles

- Improved Reliability: Teams can choose the right paradigm for each application

- Seamless Integration: Mixed environments work together smoothly

The Bottom Line: Why Choose Sides When You Don’t Have To?

What the industrial automation world is experiencing isn’t a revolution—it’s evolution. Legacy systems aren’t disappearing, but modern approaches aren’t just hype. Both have their place, their strengths, and their devoted practitioners.

PLC-Wizz understands this reality and builds accordingly. Their platform doesn’t force you to choose between respecting the past and embracing the future. Instead, it empowers you to leverage the best of both worlds.

Whether you’re maintaining ladder logic that’s been running flawlessly since before you were born or you’re writing cutting-edge structured text that pushes the boundaries of industrial programming, PLC-Wizz has your back.

Because the best tool isn’t one that works with your preferred programming style—it’s one that works with every programming style your facility needs.

Ready to work with PLC code the way it actually exists in the real world? PLC-Wizz supports every language, every paradigm, and every generation of industrial automation.